Automotive giants shift gears towards BEVs and HICEVs

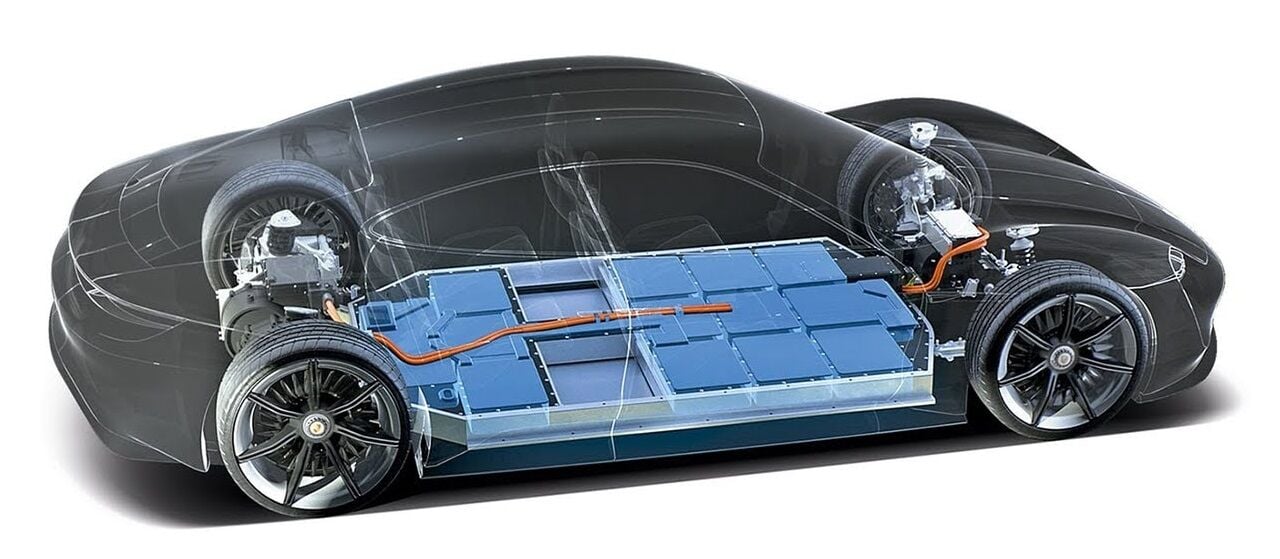

The fight against climate change has urged automotive industry leaders to focus on battery electric vehicles (BEVs) and hydrogen internal combustion engine vehicles (HICEVs). This is a critical step in reducing the greenhouse gas emissions caused by traditional internal combustion engines and contributing to a more sustainable transport future.

Original Equipment Manufacturers (OEMs) worldwide have made the bold commitment to reduce carbon dioxide emissions by 90% in 2050 compared to levels in 2020, to achieve net-zero emissions. To reach this ambitious target, significant reductions across the entire value chain are required, surpassing just vehicle technologies.

According to Deloitte’s report, Pathway to net-zero: Mastering the twofold goal of Decarbonisation and Profitability, the transition towards cleaner automotive production demands considerable investments in research and development. Additionally, the establishment of robust manufacturing capabilities for these emerging technologies is crucial.

For BEV production, the resilience of the battery supply is essential. The Fraunhofer Institute for Systems and Innovation Research reports that in 2022, China held a near-monopoly (99%) on global LFP battery production capacity. Although projections suggest a decline to 69% by 2030, China will likely continue to be a major player. This poses a considerable challenge as batteries make up about 40% of the total cost of a BEV.

As the emphasis shifts towards HICEVs and fuel cell electric vehicles (FCEVs), the development of a robust hydrogen gas station infrastructure becomes critical. However, this is not without challenges as constructing a single hydrogen station is significantly more costly than building a traditional petrol station.

Furthermore, the production of clean (green) hydrogen requires electricity for electrolysis. The distribution network and gas stations for hydrogen are yet to reach a critical mass for FCEV owners’ accessibility.

Sustainable practices

The industry-wide approach needs to encompass sustainable practices at all levels, including minimising resource usage, promoting responsible recycling of materials, and using eco-friendly methods for decommissioning vehicles at their end-of-life.

Despite the upfront investments in clean technologies and infrastructure posing short-term profitability concerns, the long-term benefits are significant. By prioritising sustainability, the industry can contribute substantially to a cleaner environment, improve air quality, and achieve cost savings through increased energy efficiency.

Investing in the workforce is also crucial in this transition. Upskilling and reskilling employees will ensure they have the necessary skills and knowledge to navigate this changing landscape.

In Thailand, the EV3.5 policy prioritises price parity incentives to speed up the adoption of EVs and attract investors to establish the country as the automotive hub of the region. Authorities are also exploring hydrogen as a sustainable alternative for the transport sector.

Thailand’s Power Development Plan (PDP) recognises hydrogen as part of its alternative fuels strategy aiming for 10 kilotonnes of oil equivalent (KTOE) of hydrogen energy consumption by 2036. This commitment is reinforced by a pilot project in collaboration with partners that resulted in the country’s first hydrogen refuelling station, showcasing Thailand’s comprehensive approach to achieving a sustainable transport future.

The automotive industry must move beyond specific technologies and adopt a holistic approach that integrates environmental awareness across its entire value chain.

This transformation, although challenging, holds immense value by improving the environment, and air quality, and offering long-term cost savings. By choosing sustainable practices across all aspects, the industry can play a significant role in shaping a greener future.

Latest Thailand News

Follow The Thaiger on Google News: