China’s home-grown cruise ship close to launch

Good luck to all who bet in her

China plans to make a big splash with the launch of its first home-grown cruise ship later this year.

It will be the nation’s first voyage into a sector dominated by European shipyards, and a critical step in reducing reliance on external sources.

Lavish, unsinkable and afloat by May

Known as the H1508, construction began in October 2019 and she is expected to be afloat by May. Sea trials will start in July, and the ship will be named and delivered by the end of this year. The H1508 will be 16 stories high with more than 2,000 rooms and a capacity of more than 5,000.

She will feature a lavish assortment of entertainment facilities, restaurants, bars, shopping malls, art galleries and spas.

Shanghai Waigaoqiao Shipbuilding says construction of China’s first home-grown cruise ship is around 90% finished. In conjunction with Italian shipbuilding giant Fincantieri, the ship is being constructed in Shanghai.

A second cruise ship known as the H1509 will be even larger than the first and has been under construction in the Shanghai yard since last year. The two vessels are owned by a joint venture between China State Shipbuilding Corporation (CSSC) and Carnival, one of the world’s largest cruise operations.

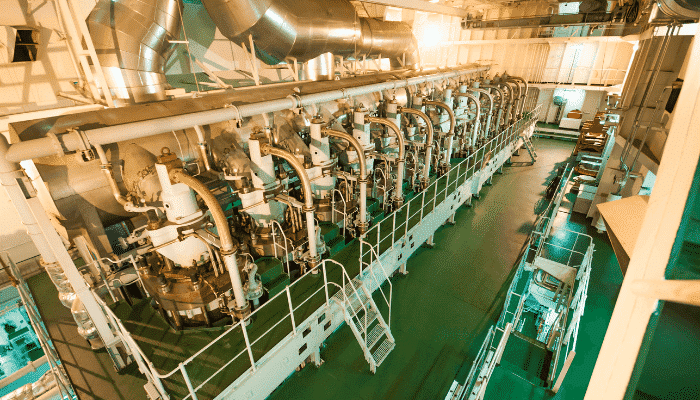

Biggest technological task

China is the largest shipbuilding nation in the world, with a combined gross tonnage of around 40 million in 2021. Cruise liners are the only advanced, high-value-added ships that China has yet to produce.

These floating cities are among the most difficult to make due to the technologies involved and the complex shipbuilding process. Building a cruise ship requires millions of parts from thousands of suppliers.

The H1508 vessel needs 25 million parts, or about five times more than the C919 aircraft, China’s home-grown passenger jet, and 13 times more components than Fuxing high-speed trains.

Materials used on cruise ships often have unique specifications. Elevators and central air conditioning must meet the needs of thousands of passengers and comply with international standards.

Little choice but to cheat

As European shipyards have dominated the cruise-ship-building industry for decades, the international standards were essentially established and evolved there. In China, few domestic suppliers have the necessary experience to make cruise ship parts.

Fewer still are familiar with international industry standards, so most of the ship has been imported. This poses considerable semantic difficulties for a “home-grown” project and adds to the already high cost.

According to the Bangkok Post, Chinese shipyards have little choice but to buy materials directly from Europe, study them, and aim to incubate a domestic supply chain that will eventually support local manufacturing.

Certification also presents a huge challenge. The global voyage of cruise ships means adherence to the specific safety and environmental standards of each country where the ship calls – everything from evacuation alarms to sewage systems.

Betting on success

Cruises have become increasingly popular in big metropolises such as Shanghai, Tianjin, and Guangzhou, as well as relatively smaller ones such as Chengdu, Qingdao, and Xiamen.

As in Thailand, gambling is banned in China. While China’s home-grown cruise ships may appear to be vast sea-going holiday camps they are, in fact, floating casinos. By 2030, there could be as many as 10 million passengers gambling away their life’s savings each with impunity outside Chinese (and Thai) territorial waters on such vessels.

Latest Thailand News

Follow The Thaiger on Google News: